With two types – fixed and adjustable – and four actuation systems – manual, hydraulic, electric and

pneumatic – together with capacities ranging from 2 rails to 12 rails (fixed type) or 2 rails to 6 rails

(adjustable type) and options including status detection switches, indicator flags and combining

beams, more than 1,000 individually tailored rail handling solutions are available.

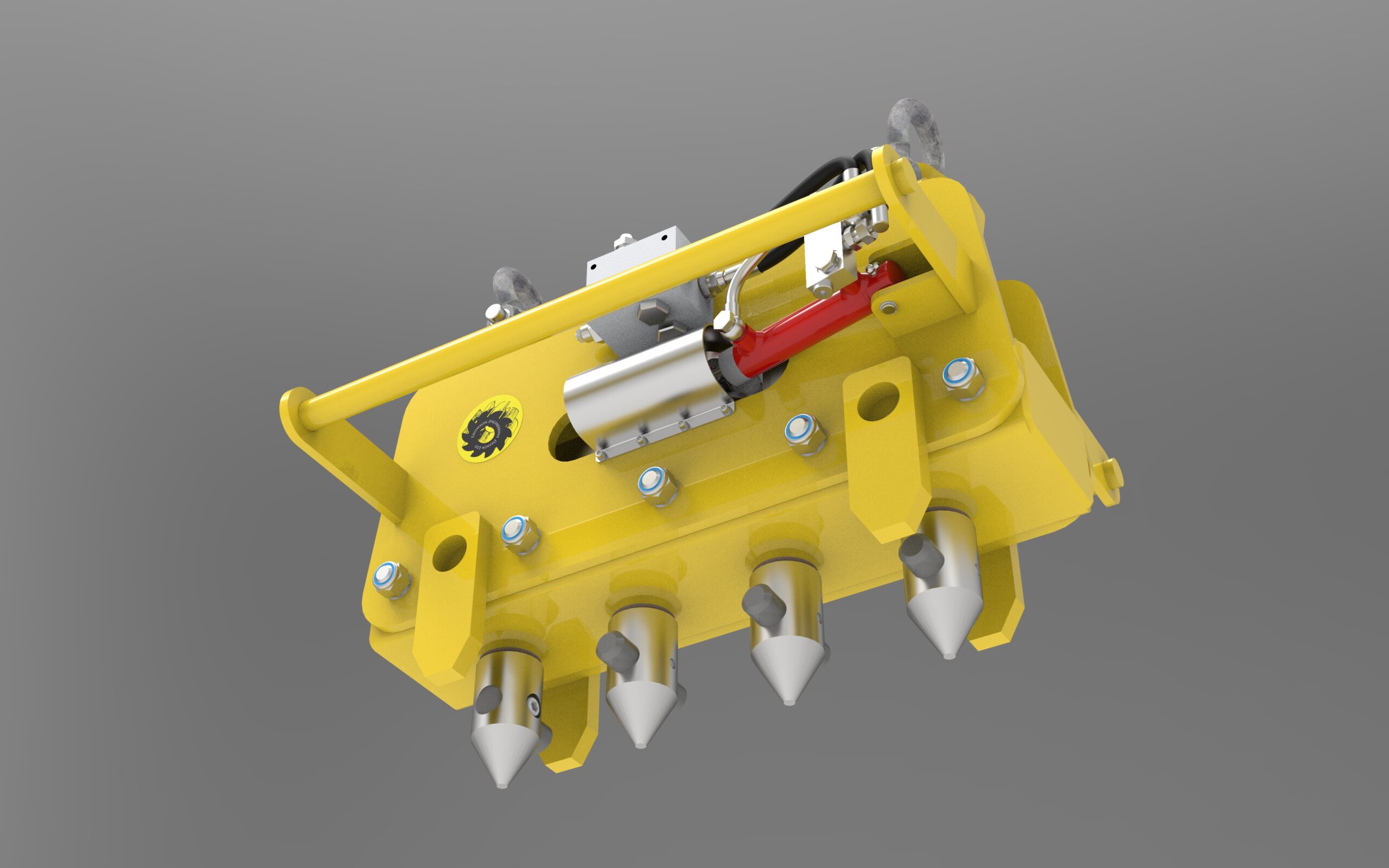

MRH14 fixed type Multi-Rail Handlers are tailored to the width of the rail foot and so can only be used

with a small range of different rail sections. They are more tolerant of dirty and dusty environments

and are slightly more robust than the MRL18 adjustable types making them the go-to choice for the

harshest environments – rail welding plants and dock yards for example.

Adjustable types can be used to handle rails with a range of different foot widths making them the first

choice as a general purpose rail bundle handler, for example in rail stock yards. Setting these units

for different rail widths takes just a few minutes and does not require tools but they are limited to a

maximum of six rails per unit. Where more rails must be handled with each lift, special combining

beams allow multiple units to be linked together.

Thomson Engineering Design can also provide spreader beams to carry a number of Multi-Rail

Handlers to support rails of any length. Normally the handlers are installed at 6m to 12m intervals

along the length of the spreader beam – depending on the stiffness of the rail sections to be handled.

Our application engineers will be pleased to provide advice on the best option for your individual needs