Rail Threading Device for Running Rails and Conductor Rails

RFT22-02 RAIL FOOT THIMBLE

The Thomson Engineering Design RFT22-02 Rail Foot Thimble is the most versatile rail threading device currently available, being able to cope with both running rails and conductor rails without any need for adjustment

By gripping the edges of the rail foot between grooved rollers the rail is fully restrained against twisting and can be easily threaded into position.

The ability to thread both running and conductor rails provides owners with greater utilisation and faster return on investment whilst its robust construction ensures a low whole-life cost of ownership.

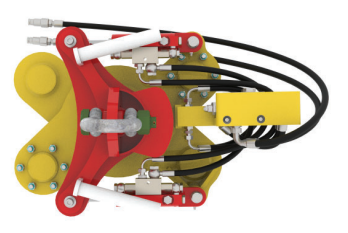

The RFT22-02 is the only device of its kind fitted with a pressure reducing valve, factory set to ensure that the system pressure is correct regardless of the settings of the host machine.

Two hydraulic cylinders are used to grip and release the rail, each of which is fitted with a pilot operated check valve to lock the cylinder in the event of a hose failure. Together, these two features make this the safest device of its type.

All the joints in the mechanism and the threader rollers themselves are fitted with replaceable bushes and grease nipples allow lubrication of all moving elements.

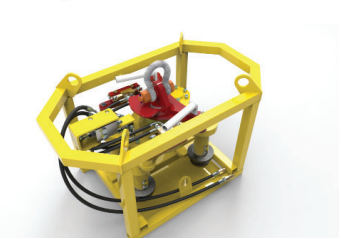

Two grab handles are provided allowing an assistant to align and guide the device onto the rail if necessary. A large safety bow shackle fitted to the top of the device makes it easy to hitch to the host machine lifting hook.

The RFT22-02 is one of a wide range of rail handling devices available from Thomson Engineering.

Design all of which have been designed and constructed following our ISO9001:2015 approved quality assurance system.

Key Features

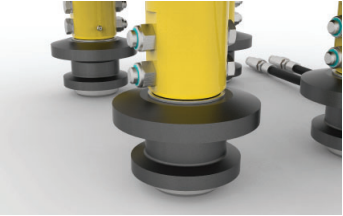

Grooved rollers on the bottom of the four legs are used to grip the edges

of the rail foot. This unique design allows the device to be fitted to both

running and conductor rails without any adjustments being made.

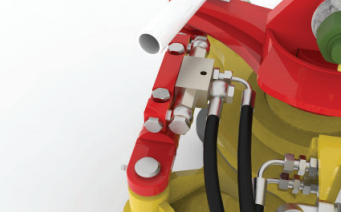

The rail foot rollers are opened and closed onto the foot of the rail by two hydraulic cylinders. Each cylinder is fitted with a pilot operated check valve to lock the cylinder in the event of a burst hose or host machine hydraulic system failure.

There is no need to adjust the pressure output of the host machine to use

this device. Instead, a pressure reducing valve fitted to the frame controls

the system pressure ensuring that the device cannot be damaged.

To fi t the RFT22-02 to the rail section it is lowered until the wider flanges

of the upper part of the rollers are resting on the rail head. The hydraulic

system is then actuated to close the bottom of the roller grooves onto the

sides of the rail foot.

Once the rollers have been closed onto the rail the device is lifted to raise

the rail and begin the threading operation.

As the device is lifted an automatic mechanism opens the jaws by 2mm

to allow a small amount of clearance between the rail foot edges and the

rollers. This makes the threading operation smoother and lowers the

friction.

The whole device is very compact weighing approximately 210kg.

A special transport stillage can be supplied which fully protects the device

during transport.

The result of many years’ experience in the design and construction of rail

threading devices, the RFT22-02 smoothly and accurately handles rails of

all types for fast, efficient operation.

Specifications

Tare Weight 210 kg

Maximum Working Load Limit 2,000 kg

Application Running Rails (Vignole Rail)

Conductor Rails

Maximum Rail Foot Thickness 23 mm

Maximum Rail Foot Width 165 mm

Maximum Hydraulic Pressure 210 Bar

Minimum Hydraulic Pressure 90 Bar

Pressure Control Pressure Reducing Valves

System Pressure 100 Bar

Construction All-Steel Fully Welded

Contact Details

All technical and sales enquiries should be directed to Thomson Engineering Design.