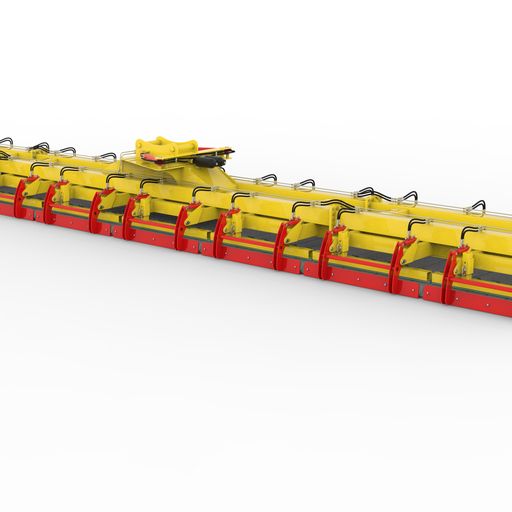

Thomson Engineering Design provide custom built grabs for handling any number of sleepers in any configuration and for any type of crane, handler or excavator.

From light weight handlers for delivery trucks to 56 sleeper train loading grabs our range encompasses every application.

Hydraulic grabs incorporate all the safety features you would expect including pressure control, check valves on the cylinders and automatic locking of the jaws when lifted. Where hydraulic power is not available, our mechanical systems grab and release the sleepers fully automatically as they are raised and lowered or we can incorporate an electric or engine driven power pack with remote control for a fully self-contained solution.

Concrete sleepers are protected from damage by highly durable urethane pads at all the contact points which also improves the grip.

Download the range brochure for more details or contact our engineering team to discuss your individual requirements.