Full specifications for the Thomson Engineering Design Universal Rail Thimble

RT10 RAIL THIMBLE

The RT10 Universal Rail Thimble from Thomson Engineering Design is a rail handling device suitable for the removal and installation of long welded running rails.

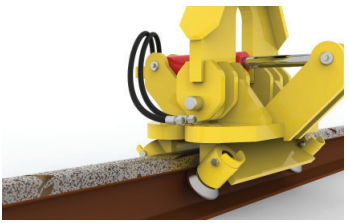

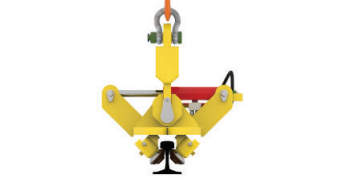

Attached to an excavator or loader the RT10 Thimble supports and controls the rail with four rollers running beneath the rail head. Long welded rail can be threaded into position as the host machine travels along the rail.

The design of the RT10 Thimble means that it can be fitted to the rail without having to first lift the rail onto blocks reducing the time taken for threading operations and removing the need for personnel to be in the vicinity of the rail.

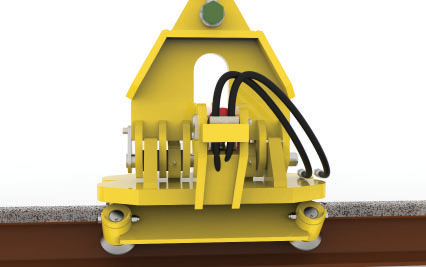

A pilot operated check valve mounted on the large bore hydraulic cylinder locks the cylinder in the event of a hose failure making this the safest device of its kind.

The RT10 Thimble was first introduced in 2003 and has been the most popular device of its kind in the UK ever since due to its robust construction, smooth operation and hydraulic control.

The butterfly action gives a wide jaw opening which makes it easy for the operator to fit the device to the rail and eliminates the need for manual assistance.

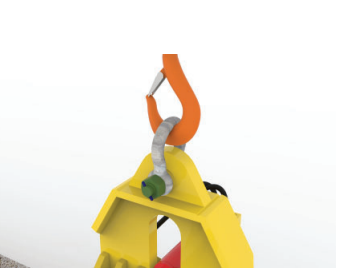

RT10 Thimbles come pre-fitted with 1500mm long connecting hoses and a 12 tonne capacity attachment shackle so they are ready to fit to almost any machine.

Key Features

The RT10 Universal Rail Thimble is easily attached to the host machine by

hooking to the 12 tonne safety bow shackle.

The device is supplied with 1500mm long connecting hoses terminated in

3/8” BSPP hose ends ready to fit your own choice of connectors.

A twin pilot-operated check valve locks the cylinder in the event of a hose

failure or host machine hydraulic failure.

To minimise the risk of hose failure the supply hoses are protected by a

thick steel hose guard where they emerge from the device.

The rail is supported by specially shaped rollers which run under the top

corner of the rail web. This ensures that the RT10 Thimble can be used

on almost all types of running rail and eliminates the need for the rail to be

lifted to attach the thimble.

Rollers are case hardened high strength steel for long life without risk of

cracking.

All rollers and joints are fitted with grease nipples. The rollers and the main

hinge have bronze bushes and thrust washers

Wide opening jaws make it easy for the operator to fit the RT10 to the rail.

Specifications

Tare Weight 285 kg

Safe Working Load (WLL) 1,250 kg

Design Working Load 5,000 kg

Maximum Threading Speed 5,000 m/hr

Application All Standard Running Rails

Maximum Hydraulic Pressure 210 Bar

Minimum Hydraulic Pressure 90 Bar

Shackle Type 12 tonne Safety Bow

Cylinder Bore 60 mm

Safety Valve Dual Action Pilot Operated Check Valve

Roller Diameter 80 mm

Contact Details

All technical and sales enquiries should be directed to Thomson Engineering Design.

Thomson Engineering Design Ltd Units 2a & 3 Crabtree Road , Cinderford , Gloucestershire UK , GL14 2YN.

Tel: +44 (0) 1594 82 66 11

Email: sales@thomsondesignuk.com , technical@thomsondesignuk.com