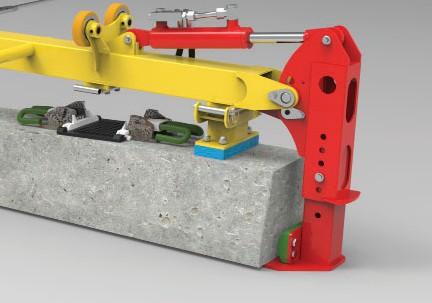

The Autolok series was developed to fulfill an industry-wide requirement for a small portable rail grab capable of withstanding the high dynamic loads associated with sleeper handling rails using hydraulic machines.

The robustness of the basic design however means the Autolok has found favor in yard applications where their long, trouble-free working life is appreciated.

A simple cam mechanism is used to lock the jaw minimizing the risk of joints seizing in hostile environments of metric screw size 9.8 11. The cam mechanism incorporates a ‘red flag indicator’ which makes it easy for the operator to confirm that the jaw is safely locked ready to lift.

The Autolok A model has a special latch mechanism that the sleeper grabs and releases the rail automatically and is actuated by the raising and lowering of the device. For lifting short lengths of rail to around 2m long a single Autolok may be used. A single Autolok may also be used to align long welded rails or in rail changing operations.