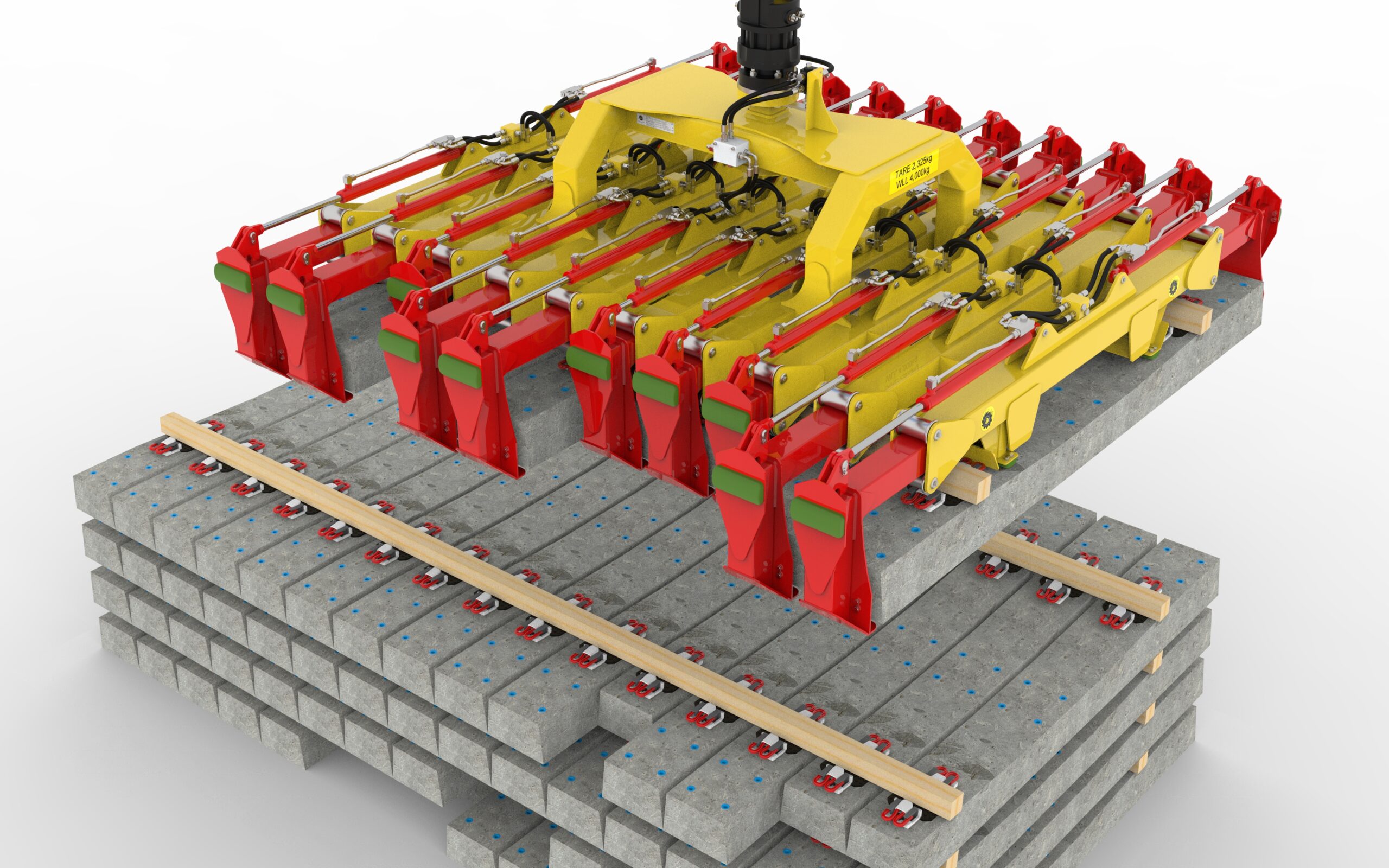

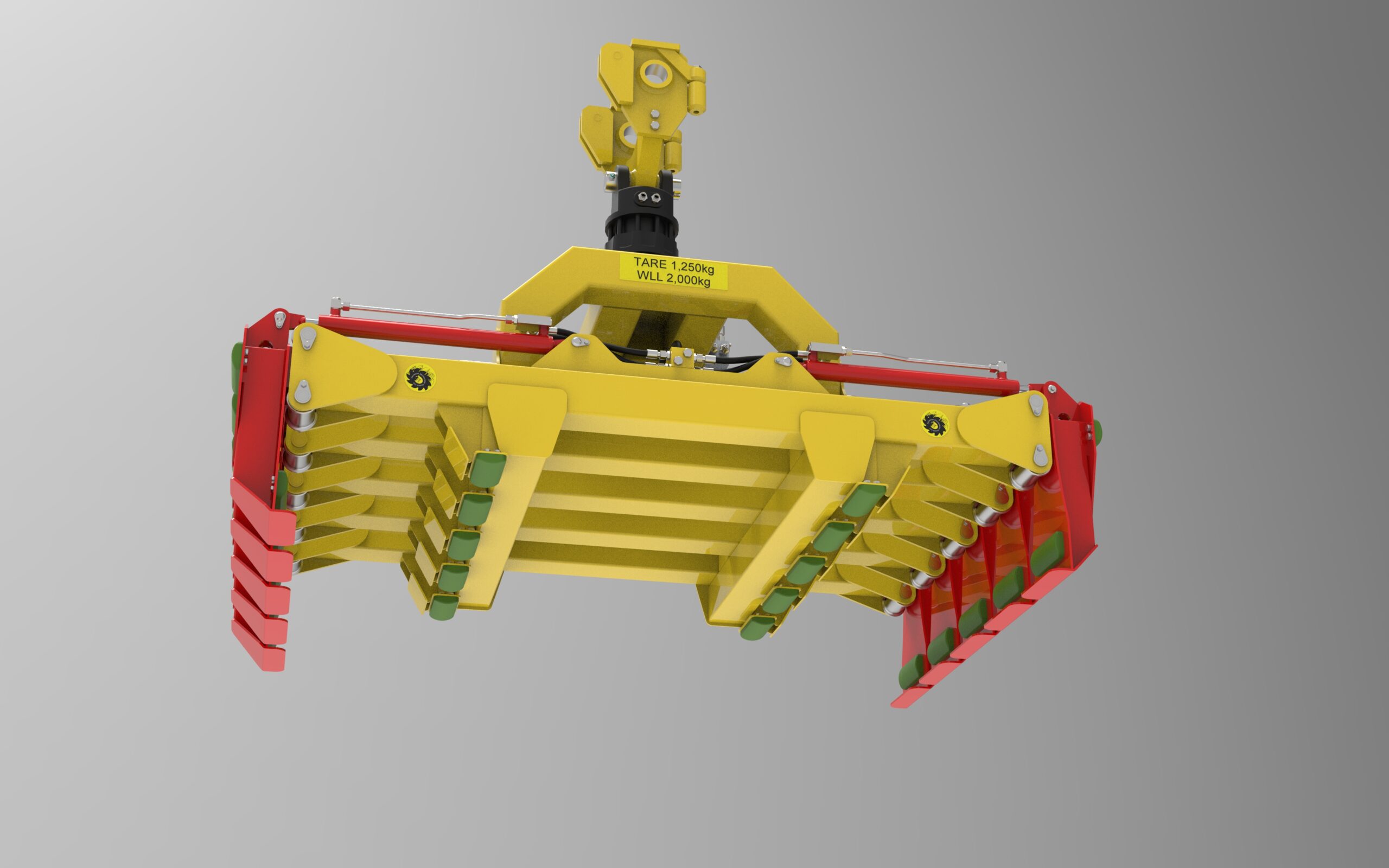

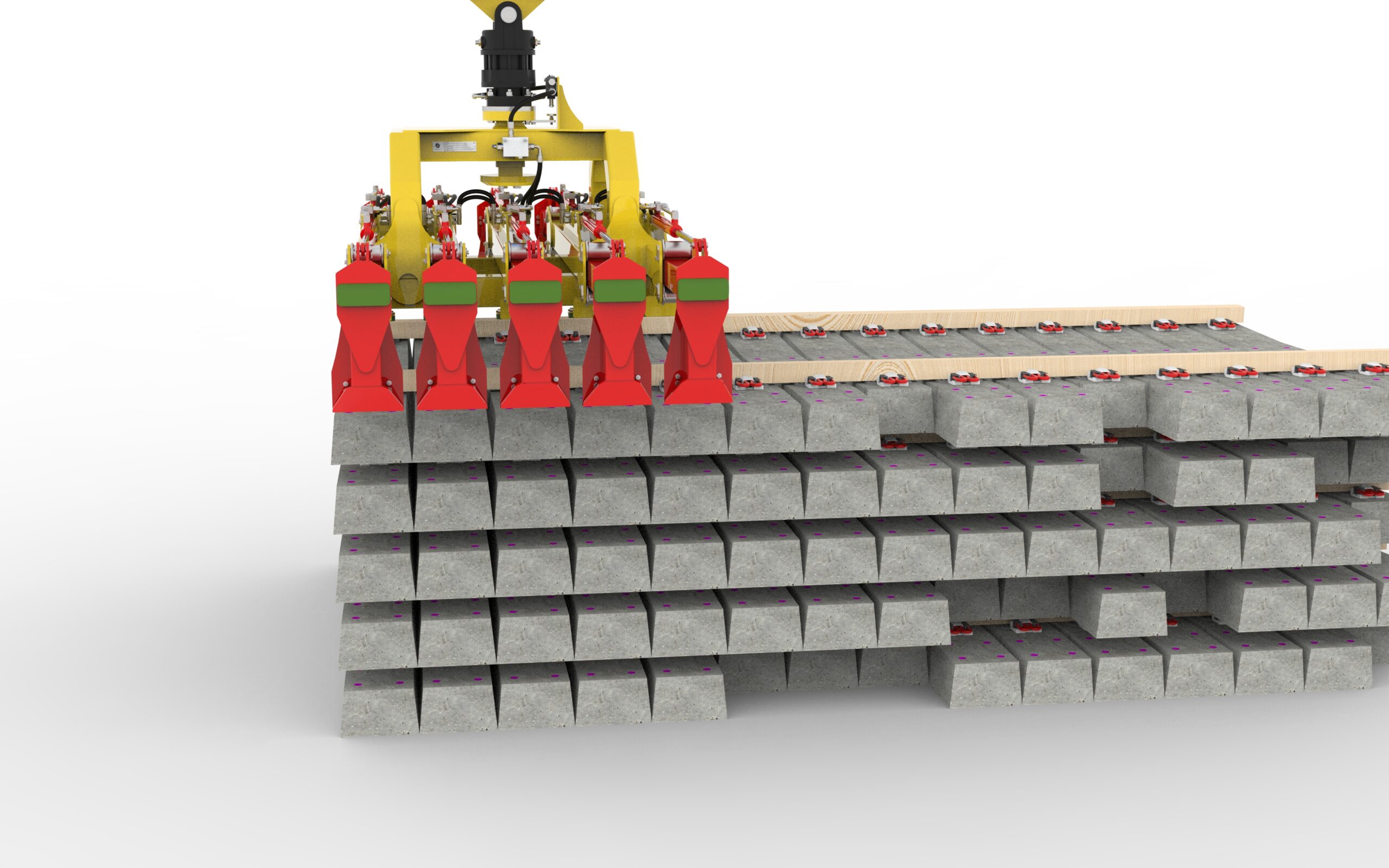

Three standard models are available for 5, 7 or 10 sleepers per lift but custom specifications are also available.

The SHB21 Sleeper Handlers are designed for full-time, heavy-duty use in depots and sleeper plants in loading, unloading and stock-piling operations and are robust enough for use with heavy excavators or materials handlers.

SHB21 Sleeper Handlers grip the sleepers with specially designed urethane pads to eliminate damage and marking of the sleeper surfaces and all models incorporate state-state-of-the-art safety features including in-built pressure control and ‘parachute valve’ protection.